Are you thinking about getting an engine hoist but worried it might be hard to put together? You’re not alone.

Many people wonder if assembling an engine hoist will take hours or require special skills. The truth is, with the right guidance, you can have your hoist ready to use faster than you expect. You’ll discover simple tips and clear steps that make assembly a breeze.

Keep reading, and you’ll gain the confidence to set up your engine hoist quickly and safely—no stress, no confusion.

Engine Hoist Basics

Understanding engine hoists starts with knowing their basics. These tools help lift heavy engines safely. They make engine removal and installation easier. Knowing the parts and types helps in assembly and use.

Engine hoists come in different styles. Each type suits different needs and spaces. Some are better for small garages. Others handle heavier engines in bigger workshops.

Types Of Engine Hoists

There are mainly two types of engine hoists: hydraulic and folding. Hydraulic hoists use fluid power to lift engines smoothly. They are strong and stable but can be heavy. Folding hoists save space and are easier to store. They may have lower lifting capacity. Choose a type based on your workspace and lifting needs.

Common Parts Included

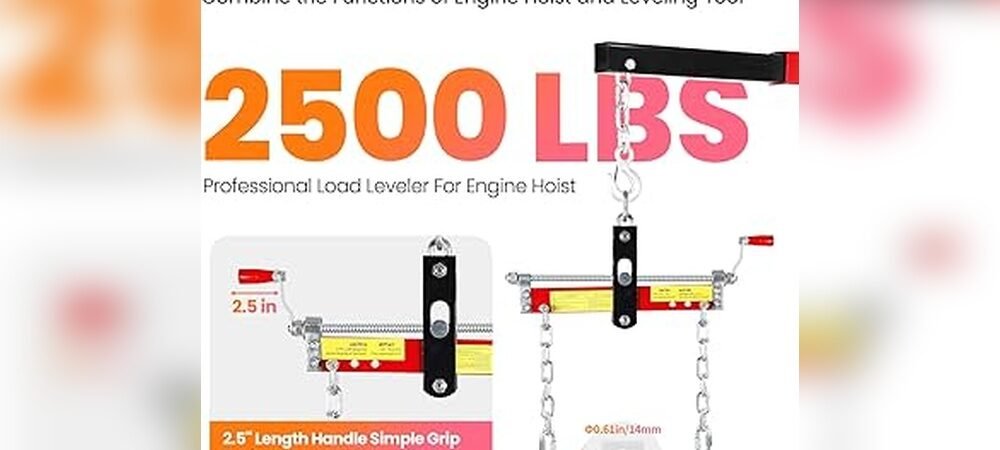

Most engine hoists come with a base, legs, and lifting arm. The base supports the hoist on the ground. Legs provide stability and often have wheels. The lifting arm extends to reach the engine. A hydraulic cylinder powers the lifting motion. Chains or hooks attach the engine to the hoist. Some models include bolts and nuts for assembly. Clear instructions usually guide the setup process.

Assembly Challenges

Engine hoists are useful tools but can be tricky to assemble. Many users face challenges during the setup process. Understanding these difficulties helps prepare for a smoother assembly. This section highlights common problems and the tools needed.

Typical Difficulties Faced

Parts can be heavy and hard to hold in place alone. Some bolts may not line up easily. Instructions might be unclear or too technical. Small pieces can get lost or mixed up quickly. Tightening bolts requires patience and care. Misalignments can cause delays and frustration.

Tools Required

A basic set of wrenches and sockets is essential. A screwdriver might be needed for some screws. A rubber mallet helps adjust parts without damage. Pliers can assist in holding small pieces steady. Safety gloves protect your hands from sharp edges. Having these tools ready speeds up the process.

Step-by-step Assembly Guide

Assembling an engine hoist may seem hard at first. This step-by-step guide breaks the process into simple parts. Follow each step carefully for a smooth setup. You will get your hoist ready in no time.

Preparing The Workspace

Clear a large, flat area to work on. Remove any obstacles or tools that could block your space. Lay down a soft cloth or cardboard to protect parts. Have all tools and parts nearby before you start. Good lighting helps you see small pieces clearly.

Connecting The Frame

Start by joining the main frame pieces. Align holes in the metal parts carefully. Use bolts and nuts provided in the kit. Tighten bolts just enough to hold parts together. Avoid fully tightening until all pieces are connected. This keeps adjustments easier later.

Attaching The Boom And Legs

Attach the boom arm to the frame using bolts. Make sure it moves freely without wobbling. Next, connect the legs to the frame base. Check all bolts for tightness but keep some play. This step gives your hoist a strong and stable base.

Securing The Hydraulic System

Install the hydraulic cylinder between the frame and boom. Connect the pump handle and check for leaks. Fill the hydraulic fluid if needed, following instructions. Test the pump by moving the handle up and down. The hoist should lift and lower smoothly without noise.

Safety Tips During Assembly

Assembling an engine hoist requires care and attention. Safety is the top priority during this process. Following safety tips helps prevent injuries and damage to the hoist. Below are some key safety tips to keep in mind while assembling your engine hoist.

Handling Heavy Components

Engine hoist parts can be heavy and awkward to move. Always lift with your legs, not your back. Use gloves to protect your hands from sharp edges. Ask for help if a part feels too heavy. Keep the workspace clear to avoid tripping. Place heavy parts on a stable surface before assembly. Never rush when handling large components.

Avoiding Common Mistakes

Read the instruction manual carefully before starting. Double-check that all parts are included and undamaged. Tighten bolts and nuts firmly but do not over-tighten. Follow the step-by-step guide in order. Use the right tools for each task. Avoid assembling the hoist on an uneven floor. Regularly inspect your work for loose or missing parts.

Expert Tricks For Easier Setup

Setting up an engine hoist can feel tough at first. Small tips can make the process smoother. These expert tricks help you save time and avoid mistakes. Follow them to build your hoist with less stress and effort.

Simple steps can improve your experience. A clear workspace and the right tools make a big difference. Let’s explore key tricks to help you set up quickly and safely.

Using Lubricants And Cleaners

Clean parts fit together easier. Use a cleaner to remove dirt and rust. Lubricants help bolts and joints move smoothly. This reduces friction and makes assembly faster. Apply lubricant on moving parts before fitting them.

Organizing Parts Before Starting

Sort all pieces on a flat surface. Group bolts, nuts, and tools by size. Check the instruction manual and match parts before assembly. This saves time and stops confusion. Knowing what you need at each step helps a lot.

Seeking Help When Needed

Some parts are heavy or awkward to hold alone. Ask a friend or family member for help. Two people make lifting safer and easier. Getting help avoids damage to parts and injury. Don’t hesitate to get assistance during setup.

Maintenance After Assembly

Maintenance after assembly is key to keeping your engine hoist working well. Regular care helps avoid breakdowns and keeps the hoist safe to use. Simple steps can extend the life of your equipment.

Regular Checks

Check the hoist for any signs of wear or damage. Look at the frame, bolts, and chains. Tighten loose parts to prevent accidents. Inspect the wheels for smooth movement. Make sure the hoist stands firm and stable before use.

Hydraulic Fluid Care

Hydraulic fluid keeps the hoist lifting smoothly. Check the fluid level often. Low fluid can cause poor lifting or damage. Replace the fluid as the manual suggests. Use the right type of fluid for your model. Clean the area around the fluid reservoir to avoid dirt getting inside.

Frequently Asked Questions

Are Engine Hoists Difficult To Assemble?

No, most engine hoists are designed for easy assembly. Clear instructions and labeled parts simplify the process. Basic tools like wrenches are usually all you need. Assembly time typically ranges from 30 minutes to an hour.

What Tools Are Needed To Assemble An Engine Hoist?

Common tools include adjustable wrenches, socket sets, and screwdrivers. Some hoists come with necessary tools included. Having a clean workspace helps speed up assembly. Following the manual closely ensures proper setup and safety.

How Long Does It Take To Assemble An Engine Hoist?

Assembly usually takes between 30 to 60 minutes. Experience with tools can reduce this time. Reading the manual before starting helps avoid mistakes. Taking your time ensures a safe and sturdy hoist.

Can One Person Assemble An Engine Hoist?

Yes, many engine hoists are designed for single-person assembly. However, having a helper can make lifting and aligning parts easier. Safety should always be a priority during assembly. Avoid rushing to prevent injury or damage.

Conclusion

Engine hoists usually come with clear instructions and few parts. Most people find assembly straightforward and quick. Basic tools and patience help to avoid mistakes. Taking time to read steps ensures proper setup. Safety checks are important before lifting any engine.

Simple designs make hoists user-friendly for beginners. With a little effort, you can assemble one confidently. This makes engine work easier and safer. Overall, assembling an engine hoist is not hard. Ready to give it a try?