If you own a diesel engine, you know how important it is to keep it running smoothly. But what do you do when your engine won’t start or feels like it’s struggling?

The answer might be simpler than you think: priming your diesel engine. Knowing how to prime a diesel engine can save you time, money, and frustration. You’ll learn step-by-step how to get your engine ready to fire up quickly and efficiently.

Keep reading, and you’ll discover tips that make this process easy—even if you’re not a mechanic. Your engine will thank you.

Why Prime A Diesel Engine

Priming a diesel engine is an important step before starting it. Diesel engines rely on fuel to move air and create power. Without fuel in the system, the engine cannot start properly.

Priming helps to remove air pockets from the fuel lines. Air in the lines stops fuel from reaching the engine. This can cause the engine to stall or not start at all.

When a diesel engine sits unused for a while, fuel can drain from the lines. Dirt and moisture can also enter the system. Priming ensures clean fuel flows smoothly to the engine.

Prevents Air Locks In Fuel System

Air locks block fuel flow. They stop the engine from getting the fuel it needs. Priming pushes air out and fills the lines with fuel. This avoids starting problems and engine damage.

Ensures Smooth Engine Start

Fuel must reach the engine quickly for a smooth start. Priming fills the fuel pump and injectors. The engine starts faster and runs better after priming.

Protects Engine Components

Dry fuel lines can cause wear and damage. Priming lubricates the fuel pump and injectors. This reduces wear and extends engine life.

Helps After Fuel System Repairs

After fixing fuel parts, air can enter the system. Priming removes trapped air and restores fuel flow. This helps the engine run normally again.

Tools Needed For Priming

Priming a diesel engine needs the right tools. Having them ready saves time and avoids frustration. Each tool plays a key role in the priming process.

These tools help remove air from the fuel system. Air in the fuel lines can stop the engine from starting. Using the proper tools ensures a smooth start.

Hand Primer Pump

A hand primer pump is essential. It helps push fuel through the lines. It removes trapped air quickly and safely. This tool is easy to use and effective.

Wrench Set

A wrench set is needed to open and close fuel line fittings. It helps loosen tight connections. A good wrench set prevents damage to parts. It fits different sizes of bolts and nuts.

Clean Container For Diesel Fuel

Use a clean container to hold diesel fuel. It avoids dirt getting into the fuel system. Clean fuel keeps the engine parts safe. Always use fresh diesel to avoid problems.

Rags Or Paper Towels

Rags or paper towels help clean spills and wipe parts. They keep the work area neat. Cleanliness prevents dirt from entering the fuel lines. Use them to dry hands too.

Safety Gloves

Wear safety gloves to protect your hands. Diesel fuel can irritate skin. Gloves also protect from sharp edges on engine parts. They improve grip on tools and parts.

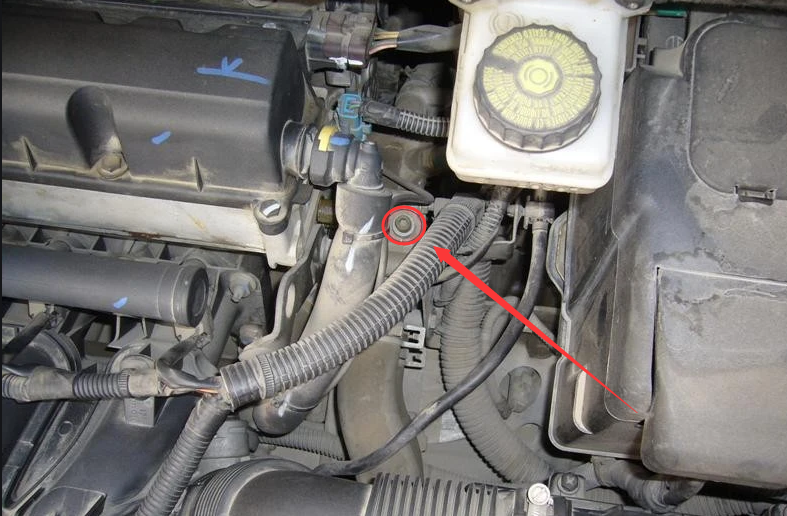

Locate The Fuel System Components

Knowing where the main fuel system parts are is key to priming a diesel engine. These parts control the flow of fuel from the tank to the engine. Finding them helps you remove air and prepare the engine to start smoothly. Look carefully around the engine area to spot these components.

Fuel Filter

The fuel filter cleans dirt and water from the fuel. It is often a small canister attached to the engine or frame. Check near the fuel lines, usually close to the tank or engine. The filter has an inlet and outlet where the fuel passes through.

Primer Pump

The primer pump helps push fuel through the system. It looks like a small pump with a lever or button. You can usually find it near the fuel filter or on the fuel lines. Press or pump it to fill the lines with fuel and remove air.

Bleed Screws

Bleed screws release trapped air from the fuel system. They are small screws or valves on the fuel filter or fuel pump. Loosen them slightly to let air escape while pumping fuel. Tighten the screws once fuel flows steadily without bubbles.

Prepare The Engine For Priming

Preparing the engine for priming is a key step before starting the diesel engine. This ensures the fuel system is ready and helps avoid damage. Follow simple steps to prepare the engine properly.

Taking time here saves effort later and keeps the engine running smoothly.

Turn Off Engine

Make sure the engine is completely off before priming. This prevents fuel from flowing while you work. Turning off the engine stops any moving parts that could cause injury. Wait a few minutes to let the engine cool down if it was running.

Check Fuel Levels

Check the fuel tank to ensure enough diesel is available. Low fuel can cause air to enter the system, making priming harder. Filling the tank before priming helps the fuel flow smoothly. Use clean diesel to avoid clogging the fuel filter.

Manual Priming Process

Priming a diesel engine manually helps remove air from the fuel system. This process ensures the engine gets enough fuel to start. Follow these simple steps to prime your engine safely and correctly.

Use The Primer Pump

Locate the primer pump on your diesel engine. It is usually a small hand-operated bulb or lever. Press or pump it slowly to push fuel through the system. This action forces air out and brings fresh fuel in.

Open Bleed Screws

Find the bleed screws near the fuel injectors or fuel lines. Use a wrench to open them slightly. This allows trapped air to escape during the priming process. Keep a container ready to catch any leaking fuel.

Pump Until Fuel Flows

Continue pumping the primer pump while watching the bleed screws. Fuel will start to flow out of the open screws. Once you see a steady stream of fuel, close the bleed screws tightly. This means the air is removed and the system is primed.

Using An Electric Primer Pump

Using an electric primer pump makes priming a diesel engine easier and faster. This tool pushes fuel into the engine’s fuel system. It removes air pockets that stop the engine from starting. The electric primer pump works with a battery. It is a safe and clean way to prepare your engine.

What Is An Electric Primer Pump?

An electric primer pump is a small device. It uses electricity to move fuel through the lines. It replaces manual pumping or cranking. The pump helps fill fuel filters and injectors quickly. It saves time and effort during engine startup.

How To Use An Electric Primer Pump

First, connect the pump to the battery. Next, attach the pump to the fuel system. Turn on the pump. You will hear the fuel moving. Watch for fuel reaching the filter or injector. Turn off the pump once fuel flows steadily. Avoid running the pump too long to prevent damage.

Benefits Of Using An Electric Primer Pump

This tool reduces air trapped in fuel lines. It prevents hard starts and engine damage. It makes the priming process less tiring. Electric pumps work faster than hand pumps. They are useful for all diesel engines, big or small.

Start The Engine After Priming

Starting the engine after priming is a crucial step in diesel engine care. It ensures the fuel system is free of air and ready to run smoothly. Proper starting prevents damage and helps the engine perform well. Follow these simple steps carefully to get your diesel engine running right after priming.

Crank The Engine

Turn the ignition key to start the engine. Do not hold the key too long; crank for about 10 seconds. If the engine does not start, wait a few seconds and try again. This action helps push the primed fuel through the system. Keep the cranking steady and avoid flooding the engine.

Listen For Smooth Operation

Pay attention to how the engine sounds after starting. A smooth, steady sound means the engine is running properly. Rough noises or sputtering could mean air is still in the fuel lines. In that case, repeat the priming process. Good engine sound shows the fuel system is working well and air is removed.

Troubleshooting Common Issues

Troubleshooting common issues helps keep your diesel engine running smoothly. Problems like air locks, fuel leaks, or difficulty starting can stop your engine from working. Knowing how to spot and fix these issues saves time and money. This section explains simple ways to solve these common problems quickly.

Air Locks

Air locks happen when air gets trapped in the fuel system. This stops fuel from reaching the engine. To fix air locks, open the bleed screws on the fuel filter or pump. Pump the fuel until you see clean fuel without bubbles. This pushes the air out and allows fuel to flow properly again.

Fuel Leaks

Fuel leaks waste diesel and can cause safety hazards. Check fuel lines, connections, and seals for cracks or damage. Tighten any loose fittings carefully. Replace damaged parts to stop leaks. Always clean spilled fuel quickly and avoid open flames near the engine.

Difficulty Starting

Difficulty starting often means fuel is not reaching the engine properly. Check for clogged filters or blocked fuel lines. Make sure the battery is charged and the glow plugs work. Try priming the fuel system again to remove air. These steps help the engine start faster and run better.

Maintenance Tips To Avoid Priming

Keeping a diesel engine ready to start without priming saves time and avoids frustration. Regular maintenance helps prevent air from entering the fuel system. This reduces the need to prime the engine before use. Simple care routines keep the engine running smoothly and reliably.

Check Fuel Lines For Leaks

Inspect fuel lines often for cracks or holes. Even small leaks let air inside the system. Replace any damaged hoses right away. Tighten loose clamps to stop air from entering. A sealed fuel system keeps diesel flowing properly.

Use Clean Fuel And Filters

Always use clean diesel fuel to avoid contamination. Replace fuel filters regularly to keep dirt out. Dirty filters cause clogs and air pockets in the system. Clean fuel and filters ensure smooth fuel flow and reduce priming needs.

Maintain Fuel Tank And Cap

Keep the fuel tank clean and free of water. Check the tank cap for a tight seal. A loose or damaged cap lets air enter the tank. This can cause air locks in the fuel lines. Proper tank care prevents air bubbles and priming issues.

Bleed The Fuel System Periodically

Bleeding removes trapped air from the fuel lines. Follow the manufacturer’s instructions for bleeding the system. Regular bleeding helps maintain fuel flow and engine start-up. This simple step can avoid many priming problems.

Frequently Asked Questions

How Do You Prime A Diesel Engine Manually?

To prime a diesel engine manually, locate the primer pump or lever. Pump it until fuel flows without air bubbles. This removes air from the fuel system, ensuring smooth engine start and operation.

Why Is Priming A Diesel Engine Important?

Priming removes air from the fuel lines and injectors. It prevents engine stalling and starting issues. Proper priming ensures efficient fuel delivery and protects the engine from damage.

How Long Should You Prime A Diesel Engine?

Priming typically takes 1 to 3 minutes or until fuel flows steadily. Avoid over-priming to prevent flooding. Follow the manufacturer’s guidelines for precise timing.

Can You Prime A Diesel Engine Without A Manual Pump?

Yes, you can prime by loosening fuel lines and using the starter motor briefly. This pushes fuel through the system and expels air. However, a manual pump is more effective and safer.

Conclusion

Priming a diesel engine is a simple but important task. It helps the engine start smoothly and run well. Follow the steps carefully to avoid air in the fuel system. Keep your tools ready and work patiently. Regular priming can save time and prevent engine damage.

Practice this skill to keep your diesel engine healthy and strong. Easy to do, worth the effort.