Are you ready to upgrade your car or home audio system but unsure how to connect the wires properly? Installing a stereo with soldering might sound tricky, but with the right steps, you can do it yourself and enjoy crystal-clear sound.

This guide will walk you through the process in simple terms, helping you avoid common mistakes and save money on professional help. By the end, you’ll have the confidence to make strong, lasting connections that keep your music playing perfectly.

Keep reading to discover how easy and rewarding soldering your stereo installation can be!

Tools And Materials Needed

Installing a stereo with soldering requires specific tools and materials. Having the right items ensures a smooth, safe, and effective setup. This section lists everything needed to complete the job.

Essential Soldering Tools

A good soldering iron is a must for joining wires firmly. Choose one with adjustable temperature control. Solder wire, preferably lead-free, connects electrical parts securely. Wire strippers remove insulation without damaging wires. Helping hands or a small clamp hold parts steady. A soldering iron stand keeps the hot tool safe when unused. Use a damp sponge or brass sponge to clean the soldering tip. Heat shrink tubing insulates and protects soldered joints.

Stereo Components Required

The stereo unit itself is the main component. Speaker wires connect the stereo to the speakers. RCA cables link the stereo to audio sources. Connectors like butt connectors or ring terminals help join wires. A wiring harness adapter matches the stereo to your vehicle’s system. Fuse holders protect the circuit from power surges. Electrical tape secures and insulates wire connections.

Safety Gear To Use

Safety glasses protect your eyes from hot solder splashes. Heat-resistant gloves shield hands from burns. Work in a well-ventilated area to avoid inhaling fumes. Use a fume extractor or fan to clear solder smoke. Wear long sleeves to prevent skin contact with hot tools. Keep a fire extinguisher nearby for emergencies. Avoid loose clothing that might catch on equipment.

Preparing Your Workspace

Preparing your workspace is the first step to a successful stereo installation with soldering. A well-organized area helps you work safely and efficiently. It also reduces mistakes and frustration. Taking time to set up the right environment makes the entire process smoother.

Organizing Tools And Parts

Gather all tools needed for soldering. Include a soldering iron, solder wire, wire cutters, and a helping hand tool. Keep stereo parts like wires, connectors, and the stereo unit nearby. Arrange everything within easy reach. This saves time and keeps you focused.

Ensuring Proper Ventilation

Soldering produces fumes that can be harmful. Work in a well-ventilated room or near an open window. Use a fan to blow fumes away from your face. Proper air flow keeps the air fresh and protects your lungs during soldering.

Setting Up A Clean Surface

Choose a flat, stable surface to work on. Clear away dust, dirt, and clutter. A clean space prevents parts from getting lost or damaged. Use a non-flammable mat or board to protect your table. This setup keeps your workspace safe and organized.

Understanding Stereo Wiring

Understanding stereo wiring is the first step to a successful installation. It helps avoid mistakes that could damage your equipment. Proper wiring ensures clear sound and safe connections.

Knowing the wire types, color codes, and compatibility makes soldering easier. This knowledge saves time and prevents frustration during the installation process.

Identifying Wire Types

Stereo systems use different wire types for power, speakers, and ground. Speaker wires usually have two conductors inside. Power wires are thicker to handle more current. Ground wires connect the system to the car’s frame for safety. Knowing the wire type helps you use the right soldering technique.

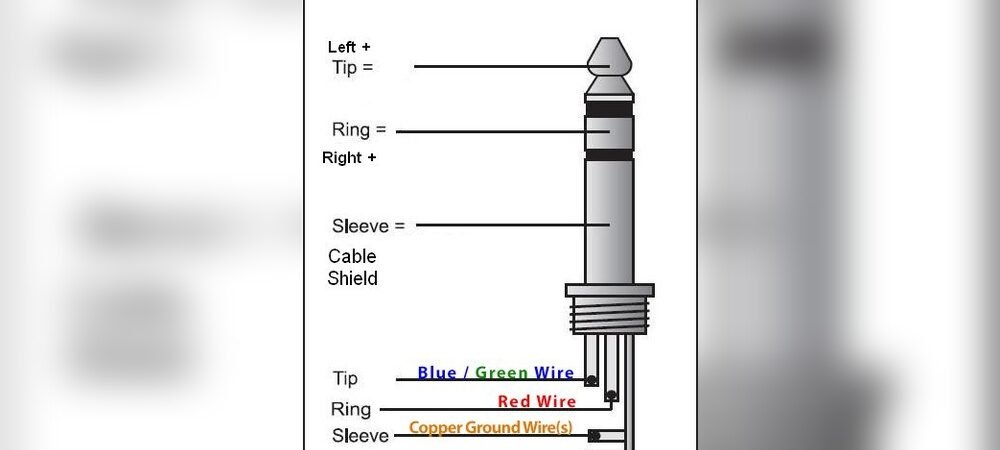

Color Codes And Their Functions

Wire colors follow a standard code to show their role. Red is usually the power wire. Black or brown often serves as ground. White and gray wires carry speaker signals. Each color helps you connect wires correctly. Mistakes in color matching can cause poor sound or damage.

Checking Wire Compatibility

Not all wires fit every stereo system. Check the wire gauge to ensure it matches your equipment. Thicker wires carry more power and reduce sound loss. Confirm that the wire insulation can handle heat from soldering. Using compatible wires keeps your stereo safe and working well.

Soldering Basics

Soldering is a key skill for installing a car stereo. It joins wires firmly and ensures a good connection. Good soldering stops wires from coming loose. It also stops sound problems caused by bad connections.

Before starting, understand some soldering basics. This helps you work safely and get strong joints. Below are some simple tips on how to heat the soldering iron, make clean joints, and avoid common mistakes.

How To Heat The Soldering Iron

Plug in the soldering iron and let it warm up. Most irons take about 2 to 3 minutes to reach the right temperature. A hot iron melts solder quickly. Do not touch the metal tip; it gets very hot.

Keep the iron clean by wiping the tip on a wet sponge. This removes old solder and dirt. A clean tip heats better and makes stronger joints.

Techniques For Clean Solder Joints

First, twist wires together for a tight fit. Heat the wire with the soldering iron tip. Then, touch the solder to the wire, not the iron. The solder should melt and flow into the wire.

Remove the solder, then the iron. Let the joint cool without moving it. A shiny, smooth joint is strong and good. Avoid dull or cracked joints.

Common Soldering Mistakes To Avoid

Do not use too much solder. It causes weak, messy joints. Avoid moving wires before the solder cools. This breaks the connection.

Do not heat wires too long. It can damage insulation or parts. Always keep the soldering iron tip clean. Dirty tips cause poor heat transfer and bad joints.

Step-by-step Installation

Installing a stereo with soldering ensures strong, reliable connections. This step-by-step guide breaks down the process into simple actions. Follow each step carefully for the best results. Proper soldering avoids loose wires and poor sound quality. This method works well for car and home stereo systems.

Stripping And Preparing Wires

Start by cutting the wires to the right length. Use a wire stripper to remove about half an inch of insulation. Be careful not to damage the wire strands. Twist the exposed wire strands to keep them tight. Clean the wires if needed to remove dirt or oil.

Tinning The Wires And Connectors

Heat your soldering iron and apply a small amount of solder to the tip. Touch the solder to the exposed wire to coat it lightly. This process is called tinning. Do the same for the connectors or terminals. Tinning helps create a better bond during soldering.

Making Secure Solder Connections

Join the tinned wire and connector together. Heat the joint with the soldering iron until hot. Feed solder into the joint, not directly on the iron. Let the solder flow smoothly and cover the connection. Remove the heat and wait for the solder to cool. Avoid moving the wires until the joint solidifies.

Insulating And Protecting Joints

Cover the soldered joints with heat shrink tubing or electrical tape. Heat shrink tubing provides a tight, durable seal. Slide the tubing over the joint before soldering, then shrink it with heat. Electrical tape works as a quick alternative. Proper insulation prevents shorts and corrosion, ensuring long-lasting connections.

Testing The Stereo Setup

Testing the stereo setup is an important step after soldering and installation. It confirms that all parts work well. This step helps find any mistakes or loose connections before final use. Careful testing keeps your stereo safe and improves sound quality. Follow the steps below to check your stereo system properly.

Checking Electrical Connections

Start by inspecting every solder joint and wire. Look for loose wires or cold solder joints. Use a multimeter to check for continuity. Ensure no wires touch that should not. Confirm ground wires connect properly to avoid noise. Secure all connections tightly before moving on.

Powering On And Audio Testing

Turn on the stereo system carefully. Watch for any sparks or unusual sounds. Adjust the volume slowly to avoid damage. Play a test audio track or radio station. Listen for clear sound from all speakers. Check bass, midrange, and treble tones for balance. Make sure no static or distortion appears.

Troubleshooting Common Issues

No sound? Double-check power and ground wires. Weak sound? Check speaker connections and volume settings. Distorted audio? Inspect solder joints for cold joints. Static noise? Look for loose cables or interference. If problems continue, test each component separately. Replace any faulty parts to restore quality sound.

Maintaining Your Stereo System

Maintaining your stereo system ensures it works well for years. Regular care helps avoid common problems. Simple steps keep sound quality clear and strong. Your stereo deserves attention to perform its best.

Regular Inspection Tips

Check all wires and connections often. Look for loose or broken solder joints. Make sure cables are not frayed or damaged. Clean dust from speakers and components carefully. Test the system to find any sound issues early.

Preventing Corrosion And Wear

Keep your stereo away from moisture and heat. Use protective sprays on metal parts to stop rust. Avoid touching wires with dirty or wet hands. Store the system in a dry, cool place. Replace worn parts before damage spreads.

Upgrading Components Safely

Choose parts that match your stereo’s specifications. Turn off power before making any changes. Use proper soldering techniques to avoid damage. Test new components thoroughly after installation. Upgrade step by step to maintain system balance.

Frequently Asked Questions

How Do I Prepare Wires For Soldering A Car Stereo?

Strip about 1/4 inch of insulation from each wire. Twist strands tightly for a clean, solid connection. This ensures better solder adhesion and signal flow.

What Tools Are Essential For Soldering Stereo Wires?

You need a soldering iron, solder wire, wire strippers, heat shrink tubing, and a helping hand tool. These tools make the job easier and safer.

How Can I Avoid Cold Solder Joints In Stereo Installation?

Heat wires evenly and apply solder to the heated wire, not the iron tip. This creates a strong, reliable electrical connection.

Should I Use Flux When Soldering Stereo Wires?

Yes, flux cleans metal surfaces and improves solder flow. It helps prevent oxidation and strengthens the joint’s durability.

Conclusion

Soldering your stereo wires makes the connection strong and lasting. Take your time to follow each step carefully. Check your work to avoid loose connections or shorts. A well-installed stereo gives better sound and fewer problems. Practice safety by working in a clean, dry space.

You can enjoy clear music with your own hands. Trust the process, and your stereo will work great. Simple tools and patience lead to good results every time. Keep learning and improving your skills with each project.