Have you ever struggled with stopping a diesel engine smoothly and safely? Knowing exactly how to shut down your diesel engine can save you time, prevent damage, and keep your equipment running longer.

Whether you’re new to diesel engines or just want to improve your skills, this guide will walk you through simple, effective steps. By the end, you’ll feel confident handling your engine shutdown every time—no stress, no guesswork. Let’s dive into how you can stop your diesel engine the right way.

Importance Of Proper Diesel Engine Shutdown

Properly shutting down a diesel engine is very important. It keeps the engine safe and helps it last longer. Stopping the engine the right way also saves money on repairs. Many problems start when the engine is turned off too fast or in the wrong way.

Taking time to shut down the engine correctly helps cool the parts. It stops damage to the engine’s fuel system and other parts. This process is simple and takes only a few extra minutes. These minutes protect your engine and make it work better.

Protects Engine Components

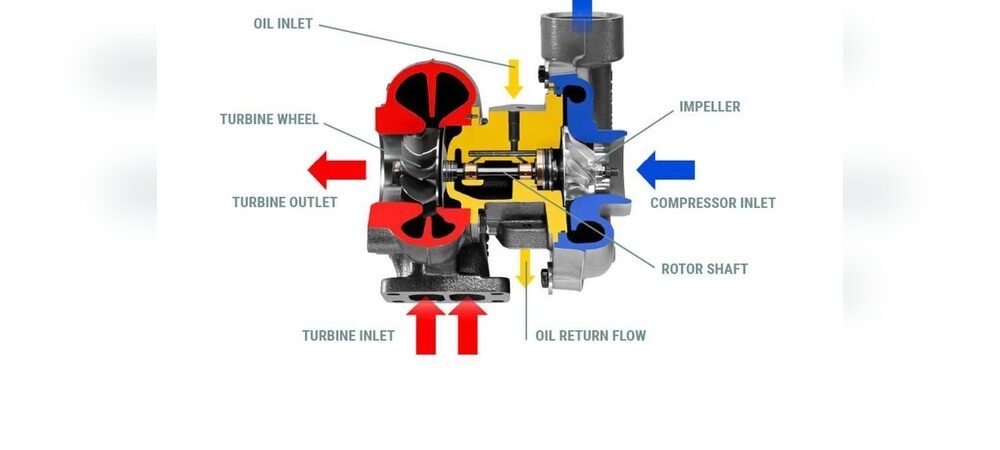

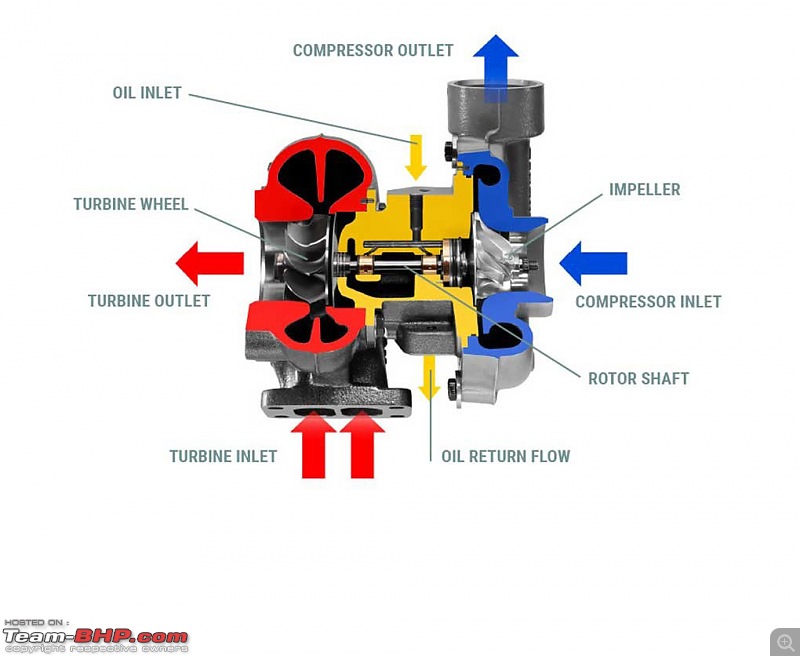

Diesel engines get very hot during use. Proper shutdown lets the engine cool down slowly. This prevents damage to parts like the turbocharger and fuel injectors. Sudden stops can cause wear and tear on these parts.

Prevents Fuel System Issues

Fuel systems in diesel engines need to cool down. Shutting down the engine properly stops fuel from overheating. This prevents clogging and damage to the fuel pump and injectors. It keeps the engine running smoothly.

Extends Engine Life

Good shutdown habits reduce engine stress. Less stress means fewer breakdowns and repairs. This helps the engine last many years longer. You save money by avoiding costly fixes and replacements.

Improves Safety

Proper shutdown lowers the risk of fire and accidents. Hot engine parts can cause burns or ignite fuel. Cooling down the engine safely protects people and property. Safety is always a top priority.

Common Diesel Engine Shutdown Methods

Stopping a diesel engine safely and efficiently is vital for its longevity and performance. Different methods exist to shut down these engines, each with its own process and use. Understanding these common methods helps in choosing the right one for your engine type and situation. This section covers the most used diesel engine shutdown techniques.

Key-off Shutdown

The key-off shutdown is the simplest and most familiar method. Turning the ignition key to the off position cuts the engine’s electrical system. This action stops the fuel pump and ignition, leading the engine to stop running. It requires no extra steps and suits many small to medium diesel engines.

Fuel Cutoff Shutdown

This method stops the fuel supply to the engine. A valve or fuel solenoid cuts off the diesel fuel flow. Without fuel, the engine cannot continue running. This shutdown is quick and prevents engine wear. It is common in larger engines and heavy machinery.

Air Intake Restriction

Air intake restriction stops the engine by limiting air supply. Diesel engines need air to burn fuel efficiently. Blocking air intake causes the engine to stall. This method is less common but useful in certain industrial engines. It helps avoid damage from abrupt stops.

Quick Shutdown Tips

Quick shutdown tips help stop a diesel engine safely and fast. Knowing the right steps prevents damage and saves time. These tips are useful in emergencies and daily operations.

Use Of Emergency Stop

The emergency stop button cuts power to the engine immediately. Press it firmly and hold for a second. This action stops the engine from running without delay. It is the safest way to shut down in urgent cases.

Always check that the emergency stop is easy to reach. This button should be visible and free from obstacles. Regularly test it to ensure it works properly.

Immediate Fuel Valve Closure

Closing the fuel valve stops fuel flow to the engine. This action quickly halts combustion and engine operation. Turn the valve clockwise until it feels tight. This step helps avoid engine damage from fuel leaks.

Use the fuel valve closure as a quick shutdown method when the engine cannot be stopped by normal means. It is a reliable backup option for urgent stops.

Safe Shutdown Practices

Shutting down a diesel engine safely extends its life and keeps it running well. Proper shutdown stops damage caused by heat and pressure inside the engine. Following safe shutdown practices helps avoid costly repairs and keeps the engine ready for the next use.

Allowing Cool-down Period

Diesel engines get very hot during use. Turning off the engine immediately can trap heat inside. Letting the engine run at low speed for a few minutes cools it down. This cool-down period prevents damage to engine parts and oil breakdown. Always wait before switching off the engine completely.

Avoiding Abrupt Stops

Stopping a diesel engine suddenly stresses the system. Abrupt stops cause pressure spikes and thermal shock. These effects reduce engine life and increase repair needs. Gradual shutdown helps engine parts adjust to temperature changes. Slow stopping preserves engine health and performance.

Checking Engine Temperature

Checking the engine temperature before shutdown is important. High temperature means the engine needs more cooling time. Use the temperature gauge or indicator to monitor heat levels. Wait until the engine cools to a safe range before turning it off. This simple step protects your engine from damage.

Shutdown Procedures For Different Diesel Engines

Shutdown procedures vary across diesel engine types. Knowing the correct steps helps protect the engine and extend its life. Each type has unique needs and safety measures during shutdown.

Automotive Diesel Engines

Turn off the engine by releasing the accelerator. Let the engine idle for a minute to cool down. Switch off the ignition key to stop the engine. Avoid turning off the engine abruptly after heavy use. This prevents damage to the turbocharger and other parts.

Industrial Diesel Engines

Reduce the load on the engine gradually. Allow the engine to run at no load for several minutes. Check oil pressure and temperature gauges during cooldown. Turn off the fuel supply once the engine is cool. Stop the engine using the control panel switch or key.

Marine Diesel Engines

Reduce engine speed slowly before shutdown. Run the engine at idle for five to ten minutes. Monitor engine temperature and oil pressure closely. Shut off the fuel supply after cooldown is complete. Use the designated engine stop button or switch to stop.

Common Mistakes To Avoid During Shutdown

Shutting down a diesel engine correctly is very important. Many people make simple errors that can cause damage. Avoiding these mistakes helps the engine last longer. It also saves money on repairs. Understanding what not to do is the first step.

Ignoring Warm-up And Cool-down

Diesel engines need time to warm up before use. Starting full speed right away can harm engine parts. The same goes for cooling down. Turning off the engine immediately after heavy work causes damage. Let the engine idle for a few minutes. This cool-down phase protects the turbocharger and oil system.

Forcing Engine Off

Switching off the engine abruptly is bad for its health. Sudden stops create stress inside the engine. It can cause cracks or wear on parts. Always follow the proper shutdown process. Use the key or button gently. Allow the engine to slow down naturally before turning off.

Neglecting Maintenance Checks

Skipping maintenance after shutdown is a common error. Checking oil levels, filters, and coolant keeps the engine safe. Dirty filters or low oil cause engine problems. Inspect these parts regularly. Maintenance helps catch issues early. It reduces breakdowns and extends engine life.

Tools And Devices For Diesel Engine Shutdown

Stopping a diesel engine safely requires the right tools and devices. These tools help control the engine’s shutdown process. They protect the engine from damage and ensure safety. Using proper shutdown devices also saves fuel and extends engine life.

Diesel engine shutdown tools come in two main types: automatic and manual. Each type has its own benefits and uses. Understanding both helps you choose the best method for your needs.

Automatic Shutdown Systems

Automatic shutdown systems stop the engine without human help. Sensors detect problems like low oil pressure or high temperature. When a fault appears, the system cuts fuel supply to stop the engine. This prevents serious engine damage quickly and safely.

Some systems also monitor battery voltage and coolant levels. They act fast to avoid breakdowns. These systems are common in large diesel engines and industrial machines. They reduce the risk of accidents and save repair costs.

Manual Controls

Manual controls let the operator stop the engine by hand. Common tools include ignition switches and fuel shutoff valves. Turning the switch or closing the valve cuts off fuel, stopping the engine.

Manual shutdown requires attention and care. Operators must follow safety steps to avoid engine issues. This method works well for smaller engines or when automatic systems are unavailable. It gives users direct control over the engine.

Frequently Asked Questions

How Do I Safely Stop A Diesel Engine?

To safely stop a diesel engine, reduce the throttle to idle. Allow it to run for a few minutes to cool down. Then, turn off the ignition key or switch. This prevents engine damage and prolongs its life.

What Are The Steps To Shut Down A Diesel Engine?

First, let the engine idle for 3-5 minutes. This cools the turbocharger and internal components. Next, turn off any accessories. Finally, switch off the ignition to stop the engine completely.

Can I Stop A Diesel Engine Abruptly?

Stopping a diesel engine abruptly is not recommended. It can cause turbocharger damage and engine wear. Always let the engine idle before shutdown to ensure proper cooling and avoid costly repairs.

Why Should I Idle The Diesel Engine Before Stopping?

Idling the diesel engine before stopping helps cool the turbocharger. It prevents oil coking and damage to engine parts. This practice extends engine life and maintains performance.

Conclusion

Stopping a diesel engine is simple with the right steps. Always turn off the fuel supply first. Then, allow the engine to cool down before handling it. Avoid rushing the process to keep safety in mind. Regular practice helps you stop engines quickly and safely.

Follow these tips every time to protect your engine. Keep your diesel engine in good shape by stopping it properly. This small effort saves time and money later.