Have you ever wondered what keeps your engine running smoothly every time you start your car? One small but powerful part working behind the scenes is the crankshaft sensor.

If your vehicle suddenly struggles to start or runs unevenly, this tiny component could be the culprit. Understanding the role of the crankshaft sensor can save you time, money, and frustration by helping you spot issues early. Keep reading to discover how this sensor affects your engine’s performance and why it’s so important for your car’s health.

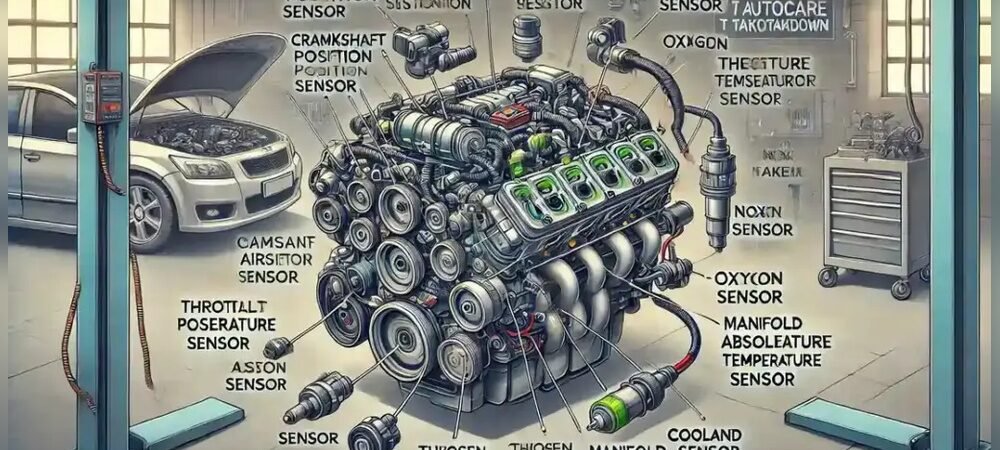

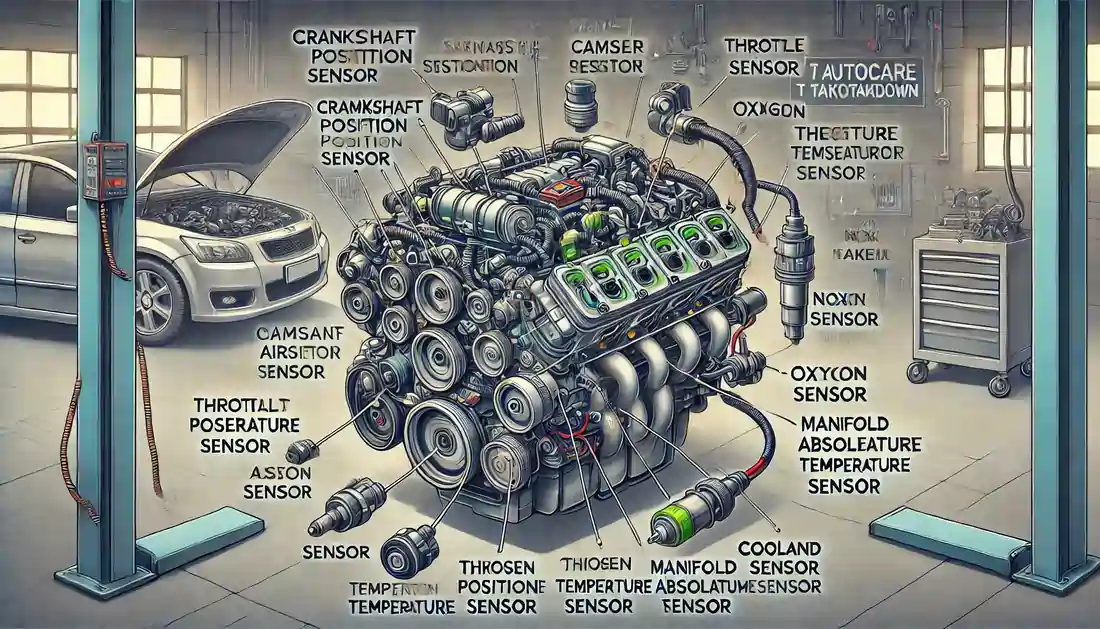

Crankshaft Sensor Basics

The crankshaft sensor is a small but vital part of a car’s engine system. It helps the engine control unit (ECU) know the exact position of the crankshaft. This information is important for timing the ignition and fuel injection. Without a working crankshaft sensor, the engine may not run smoothly or might not start at all.

Understanding the basics of the crankshaft sensor helps you see why it is so important. It plays a key role in engine performance and efficiency. Let’s explore what the sensor does and the types available.

What A Crankshaft Sensor Does

The crankshaft sensor monitors the position and speed of the crankshaft. It sends signals to the ECU about the crankshaft’s rotation. The ECU uses this data to control spark timing and fuel delivery. This process ensures the engine runs efficiently and avoids misfires. The sensor helps the engine know when to ignite fuel in each cylinder.

Types Of Crankshaft Sensors

There are mainly two types of crankshaft sensors. The first type is the magnetic sensor. It uses a magnetic field and a metal reluctor ring to create a signal. The second type is the Hall effect sensor. It uses a voltage signal produced by a magnetic field. Both types send important timing data to the ECU. The choice depends on the vehicle make and model.

How The Sensor Works

The crankshaft sensor is a small but vital part of a car’s engine system. It helps the engine know the exact position and speed of the crankshaft. This information is necessary for the engine to work smoothly and efficiently. Understanding how this sensor works can help you appreciate its role in your vehicle.

Signal Generation Process

The sensor uses a magnetic or Hall effect principle to create signals. As the crankshaft spins, metal teeth or notches pass by the sensor. This causes a change in the magnetic field or voltage. The sensor converts these changes into electrical pulses.

Each pulse represents a specific position of the crankshaft. The faster the crankshaft spins, the more pulses the sensor produces. These pulses form a pattern that matches the crankshaft’s rotation.

Interaction With Engine Control Unit

The sensor sends the electrical pulses to the Engine Control Unit (ECU). The ECU reads these signals to understand the crankshaft’s position and speed. It uses this data to control fuel injection and ignition timing.

Accurate sensor signals help the ECU keep the engine running efficiently. If the sensor sends wrong or no signals, the engine may misfire or stall. The ECU depends on the crankshaft sensor to make real-time decisions.

Importance In Engine Performance

The crankshaft sensor helps the engine know the exact position of the crankshaft. This information is key for smooth fuel injection and ignition timing. Without it, engine performance can drop, causing rough idling or stalling.

Impact On Ignition Timing

The crankshaft sensor tells the engine when to fire the spark plugs. It tracks the crankshaft’s position and speed. This data helps the engine control unit decide the exact moment to ignite the air-fuel mix. Proper ignition timing improves power and fuel efficiency. Incorrect timing can cause engine knocking or poor performance. The sensor ensures smooth engine operation and prevents damage.

Effect On Fuel Injection

The crankshaft sensor also guides fuel injection timing. It signals when to inject fuel into the combustion chamber. Accurate timing ensures the fuel burns completely and efficiently. This reduces emissions and saves fuel. Poor sensor data can lead to misfires or rough idling. The sensor helps keep the engine running clean and steady.

Common Symptoms Of Sensor Failure

The crankshaft sensor plays a key role in engine performance. It tells the engine control unit the position and speed of the crankshaft. If this sensor fails, the engine may not run smoothly. Recognizing the symptoms early can help avoid bigger problems.

Engine Stalling And Misfires

One common sign of sensor failure is engine stalling. The engine may stop suddenly while driving. Misfires can also happen, causing the engine to run rough. These issues occur because the sensor sends wrong signals to the engine control unit.

Starting Difficulties

A faulty crankshaft sensor can cause trouble starting the car. The engine might crank but not start. Sometimes, it takes several attempts before the engine fires up. This happens because the sensor does not properly detect the crankshaft’s position.

Diagnosing Sensor Issues

Diagnosing crankshaft sensor issues helps keep your engine running smoothly. The sensor plays a key role in engine timing and performance. Problems with this sensor can cause engine stalling, poor acceleration, or no start at all. Identifying sensor faults early saves time and money on repairs. Testing the sensor correctly shows if it needs replacement or cleaning.

Testing Methods

Start by checking the sensor’s electrical resistance with a multimeter. Compare readings to the vehicle’s manual specifications. Next, inspect the sensor signal output while the engine runs. Use an oscilloscope for clear waveform patterns. A weak or no signal usually means sensor damage. Visual checks also help. Look for cracks, corrosion, or loose wiring around the sensor. These signs suggest sensor failure or connection issues.

Tools Needed

A digital multimeter is essential for resistance and voltage checks. An oscilloscope provides detailed sensor signal analysis. Basic hand tools like screwdrivers and wrenches help remove the sensor safely. You may need a scan tool to read error codes from the car’s computer. These codes often point directly to crankshaft sensor problems. Clean cloths and contact cleaner improve testing accuracy by removing dirt and grease.

Replacing And Maintaining The Sensor

Replacing and maintaining the crankshaft sensor keeps your engine running smoothly. This sensor helps the engine control unit know the crankshaft’s position. A faulty sensor can cause poor engine performance or stalling. Regular checks and timely replacement prevent costly repairs.

Replacement Steps

First, disconnect the car battery to avoid electric shocks. Locate the crankshaft sensor near the engine block. Remove any components blocking access to the sensor. Carefully unplug the sensor connector. Unscrew the sensor from its position using the right tools. Install the new sensor by screwing it in place. Reconnect the sensor plug securely. Replace any removed parts. Finally, reconnect the car battery and start the engine to check sensor function.

Maintenance Tips

Keep the sensor and its area clean from dirt and oil. Check the wiring and connector for damage regularly. Avoid using harsh chemicals near the sensor. Inspect the sensor during routine engine maintenance. Replace the sensor immediately if you notice engine misfires or rough idling. Proper maintenance extends the sensor’s life and improves engine reliability.

Advancements In Sensor Technology

Sensor technology has improved a lot in recent years. These changes help crankshaft sensors work better. The sensors are now more accurate and last longer. They also fit well in different engine types. These advancements help engines run smoothly and use less fuel.

New Sensor Designs

New designs make crankshaft sensors smaller and stronger. They use better materials that resist heat and vibration. Some sensors use digital signals instead of old analog ones. Digital signals give clearer data to the engine control unit. This helps the engine adjust timing and fuel more precisely.

Advanced designs also include sensors with built-in diagnostics. These sensors can tell if they are failing. This makes car repairs easier and faster. New sensors also use less power, which helps save fuel.

Integration With Modern Engines

Modern engines need sensors that work with many systems. Crankshaft sensors now connect directly to the engine control unit. This allows real-time data sharing for better engine management. The sensors also support features like variable valve timing and cylinder deactivation.

Integration means sensors help reduce emissions and improve performance. They work with other sensors to create a complete engine picture. This teamwork helps engines run cleaner and last longer.

Frequently Asked Questions

What Is The Function Of A Crankshaft Sensor?

A crankshaft sensor monitors the crankshaft’s position and speed. It sends this data to the engine control unit (ECU). This helps optimize fuel injection and ignition timing for smooth engine performance.

How Does A Faulty Crankshaft Sensor Affect The Engine?

A faulty sensor can cause engine misfires, stalling, or hard starts. It disrupts the ECU’s timing, leading to poor fuel efficiency and rough idling.

Where Is The Crankshaft Sensor Located In A Car?

The crankshaft sensor is usually near the crankshaft pulley or flywheel. Its position allows it to detect the crankshaft’s rotation accurately.

Can I Drive With A Bad Crankshaft Sensor?

Driving with a bad sensor is risky. It can cause engine stalls or reduced power. Repairing or replacing it promptly is recommended for safety.

Conclusion

The crankshaft sensor helps the engine run smoothly and efficiently. It sends important signals about engine speed and position. This information keeps the ignition and fuel systems working well. Without it, the engine may stall or lose power. Understanding this part helps you know more about your car’s health.

Regular checks can prevent bigger problems. Keep the sensor clean and replace it if needed. This small part plays a big role in your vehicle’s performance.