Are you confused about which hoist to choose for your lifting needs? Understanding the difference between a chain hoist and a hydraulic hoist can save you time, effort, and money.

Whether you’re working in a workshop, on a construction site, or handling heavy equipment, picking the right hoist makes all the difference. You’ll discover how these two types of hoists work, their key advantages, and which one fits your specific tasks best.

Keep reading to make an informed decision that suits your needs perfectly.

Chain Hoist Basics

Chain hoists are common tools used to lift heavy objects safely and efficiently. They are popular in many industries for moving loads vertically. Understanding the basics of chain hoists helps in choosing the right lifting device for your needs.

These hoists are manual or powered and use a chain to lift and lower items. Their simple design makes them reliable and easy to use in many settings.

Design And Components

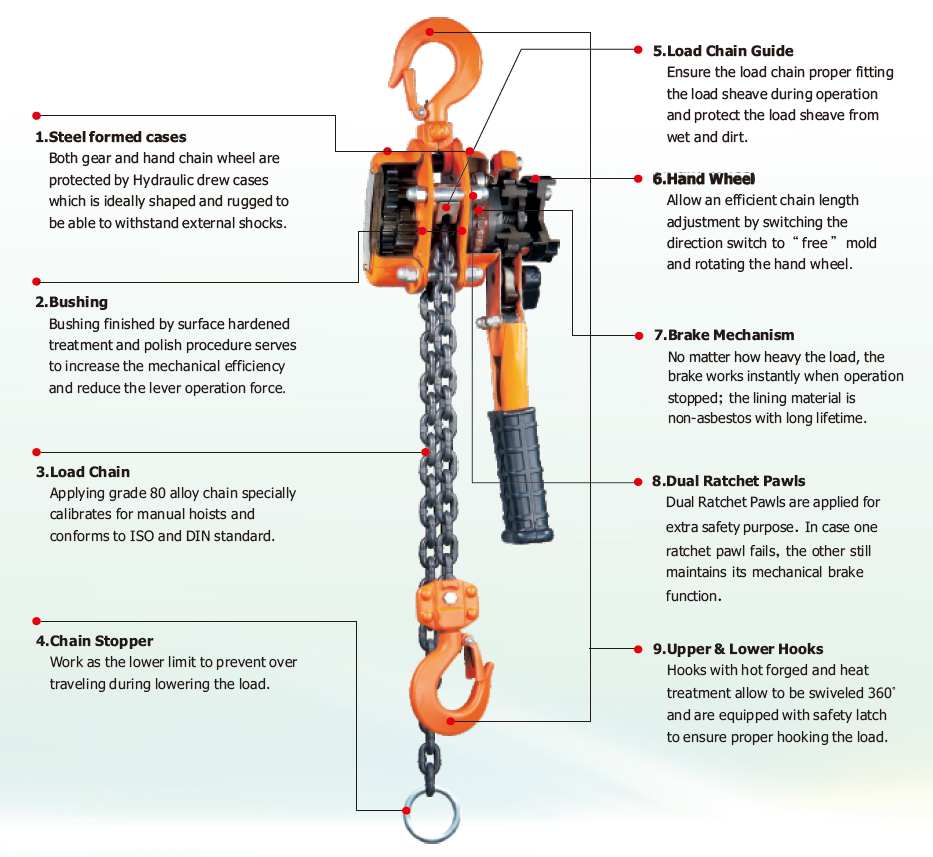

A chain hoist has a few key parts. A hook holds the load securely. A chain runs through gears inside the hoist body. The gears increase lifting power. A hand chain allows the user to operate the hoist by pulling it. The frame keeps all parts together and protects the gears.

How It Works

Pulling the hand chain turns the gears. The gears then pull the load chain up or let it down slowly. This action lifts or lowers the load. The gears multiply the force, so you can lift heavy weights easily. The hoist locks in place to hold the load steady.

Common Uses

Chain hoists are used in workshops, factories, and construction sites. They lift engines, machines, and building materials. They work well in tight spaces where cranes cannot fit. Their portability and ease of use make them ideal for many lifting jobs.

Hydraulic Hoist Basics

Hydraulic hoists use fluid pressure to lift heavy loads. They are common in many industries for moving large objects. These hoists rely on a simple but strong system. Understanding their design and function helps to see their advantages.

Hydraulic hoists offer smooth and controlled lifting. Their power comes from hydraulic fluid, which moves under pressure. This makes lifting easier and safer in many cases.

Design And Components

A hydraulic hoist has a few main parts. It includes a hydraulic pump, cylinder, and fluid reservoir. The pump moves the hydraulic fluid. The cylinder uses this fluid to create lifting force. A valve controls the fluid flow. Chains or hooks attach to the load.

How It Works

The pump pushes fluid into the cylinder. This pressure moves the piston inside the cylinder upward. The piston lifts the load connected to the hoist. To lower the load, the valve releases fluid back to the reservoir. This process allows precise control over lifting and lowering.

Common Uses

Hydraulic hoists are often used in construction and automotive repair. They lift heavy materials and vehicle parts. Factories use them for moving heavy equipment. Their ability to handle large weights with smooth motion makes them ideal for many tasks.

Comparing Lifting Mechanisms

Comparing lifting mechanisms helps to understand how chain hoists and hydraulic hoists work differently. Each type uses a unique method to lift heavy loads. This affects their use, power source, and efficiency. Knowing these differences can guide you in choosing the right hoist for your needs.

Power Sources

Chain hoists rely on manual power or electricity. Manual chain hoists use hand force to lift loads. Electric chain hoists use motors to reduce effort. Hydraulic hoists operate using fluid pressure. They need a pump to move hydraulic fluid. This pump can be manual or powered by electricity. Hydraulic systems provide smooth and strong lifting power.

Load Handling

Chain hoists lift loads using a chain wrapped around a drum. The chain moves to raise or lower the load. This method works well for moderate weights. Hydraulic hoists use cylinders and pistons to lift loads. The hydraulic pressure pushes the piston up. This system handles heavier loads with ease. Hydraulic hoists offer more control in precise lifting tasks.

Efficiency

Chain hoists are simple and easy to maintain. They work best for lighter to medium loads. Manual chain hoists need physical effort, which can be tiring. Electric chain hoists save energy and time. Hydraulic hoists are highly efficient for heavy lifting. They require less force and offer smooth operation. Hydraulic systems need regular checks to avoid leaks and maintain power.

Safety Features

Safety features are crucial for both chain hoists and hydraulic hoists. These features help prevent accidents and protect users during lifting tasks. Understanding the safety aspects of each hoist type ensures proper and secure operation.

Chain Hoist Safety

Chain hoists have built-in brakes that stop the load instantly if the power fails. The load chain is made of strong steel to avoid breaking. Hooks include safety latches to keep the load secure. Overload protection prevents lifting beyond the hoist’s limit. Regular inspection of chains and hooks is important for safe use.

Hydraulic Hoist Safety

Hydraulic hoists use valves to control lifting speed and stop the load safely. They have pressure relief valves to avoid overloading. The hydraulic fluid system is sealed to prevent leaks and maintain pressure. Safety locks hold the load in place during maintenance. Checking fluid levels and seals helps keep the hoist safe.

Maintenance Needs

Maintenance needs differ between chain hoists and hydraulic hoists. Proper care ensures safety and extends the tool’s life. Each type requires specific attention to work well and avoid breakdowns.

Chain Hoist Care

Keep the chain clean and free from dirt. Dirt can cause the chain to wear out fast. Lubricate the chain regularly with the right oil. Check for rust or damage on the chain links. Replace any worn or broken parts immediately. Inspect the hoist’s hooks and safety latches often. Store the chain hoist in a dry place to avoid rust. Test the hoist before each use to ensure smooth operation.

Hydraulic Hoist Care

Monitor the hydraulic fluid level regularly. Low fluid can cause the hoist to fail. Change the hydraulic oil as the manufacturer suggests. Look for leaks in hoses and seals. Replace damaged hoses without delay. Clean the hoist to prevent dirt from entering the system. Check the pump and valves for proper function. Store hydraulic hoists in a cool, dry area to protect parts.

Cost And Durability

Cost and durability are key factors when choosing between a chain hoist and a hydraulic hoist. Both types serve similar functions but differ in price and how long they last. Understanding these differences helps you pick the best tool for your needs and budget.

Initial Investment

Chain hoists usually cost less upfront. Their simple design and common parts make them cheaper to buy. Hydraulic hoists have more complex systems, which raises their price. The extra cost comes from pumps and fluid systems. For small projects, chain hoists fit well. Bigger jobs might require the power of hydraulic hoists despite higher costs.

Long-term Expenses

Chain hoists need less maintenance, lowering long-term costs. They have fewer parts that break or wear out. Hydraulic hoists need regular checks and fluid changes. Repairs can be costly if the hydraulic system fails. Durability depends on use and care. Chain hoists last long with proper handling. Hydraulic hoists can also last but need more attention.

Choosing The Right Hoist

Choosing the right hoist is important for safety and efficiency. The choice depends on the type of work and the environment. Understanding these factors helps in selecting a hoist that fits your needs.

Application Considerations

Think about the weight and size of the load. Chain hoists work well for medium loads and precise control. Hydraulic hoists handle heavier loads and provide smooth lifting power. Consider how often you will use the hoist. Chain hoists are good for lighter, frequent tasks. Hydraulic hoists suit heavy or tough jobs that need more strength.

Work Environment Factors

Look at the location where the hoist will operate. Chain hoists are simple and can work in many environments, including indoors and outdoors. Hydraulic hoists need cleaner and drier places to avoid damage. Also, check the power source availability. Chain hoists may be manual or electric. Hydraulic hoists usually need a hydraulic power unit. Noise and space limits also matter. Chain hoists are quieter and smaller. Hydraulic hoists may be louder and bulkier.

Frequently Asked Questions

What Is A Chain Hoist Used For?

A chain hoist is used to lift heavy loads vertically. It employs a chain and pulley system for manual or powered lifting, ideal for construction, manufacturing, and maintenance tasks.

How Does A Hydraulic Hoist Work?

A hydraulic hoist uses fluid pressure to lift loads. It converts hydraulic energy into mechanical force, providing smooth and powerful lifting, often used in automotive and industrial applications.

What Are The Main Differences Between Chain And Hydraulic Hoists?

Chain hoists use chains and pulleys, relying on manual or electric power. Hydraulic hoists use fluid pressure for lifting. Chain hoists suit lighter loads; hydraulic hoists handle heavier, more precise lifting tasks.

Which Hoist Is Safer For Heavy Lifting?

Hydraulic hoists are generally safer for heavy lifting due to controlled, steady movement and built-in pressure relief. Chain hoists require careful handling to avoid sudden drops or chain failure.

Conclusion

Chain hoists and hydraulic hoists serve different lifting needs. Chain hoists work well for lighter loads and precise control. Hydraulic hoists handle heavier weights with smooth lifting power. Choosing the right hoist depends on your task and environment. Both types offer reliable and safe lifting options.

Understanding these differences helps you pick the best tool. Use this knowledge to make a smart, efficient choice. Safety and efficiency matter most in any lifting job.